Tanforloc and Propell Project: Zero Waste

The future of our industry based on sustainability

Leather Quimica is part of the Mathiesen Group, a company based in Chile, a leader in global trade and the supply of raw materials for the chemical industry, plastics, mining, construction materials, food, tanning, animal nutrition, paper, and cellulose, among others.

The company has been investing in R+D+i for years, with a clear idea about the future of our industry based on adaptation and sustainability. As a result of this idea, we participated in the TANFORLOC PROJECT along with the Centre for Forest Science and Technology (CTFC), Combalia, and Innedit Innova.

The main objective of this research and development project is to obtain tannins and other aromatic compounds from the bark of native white pine forests to be used for leather tanning.

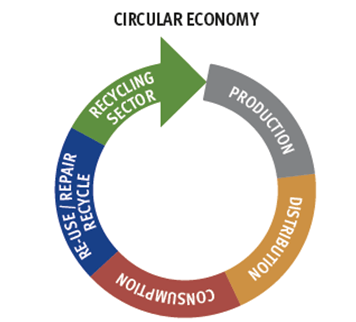

With this project, we aim not only to mitigate climate change but also to promote the use of local raw materials, such as white pine bark, to obtain bio-products within the framework of the circular bio-economy.

“These projects have been co-financed by ACCIÓ”

Agència per la Competivitat de la empresa (ACCIÓ)

At the same time, we are also carrying out the PROPELL project. In this case, the objective is to recover a by-product of the leather industry, the offcuts, eliminating the metallic components and studying their recovery.

The protein part will be isolated and hydrolyzed to be used as a tanning agent for the skins, thus improving their organoleptic properties. Additionally, research will be conducted to explore its application in other non-tanning sectors, such as fertilizers, binders, or cosmetics.

All these new products are part of the new –Z range that is being developed for the tanning market and is being completed day by day to reach the goal of Zero waste.

Leather Quimica thus ratifies its commitment to the tanning industry and focuses on a more sustainable future.

Leather Quimica thus ratifies its commitment to the tanning industry and focuses on a more sustainable future.

Benefits -Z

- Sustainability

- Green technology

- Biodegradable

- Cost optimization

- Circular economy